Our Services

Providence Corrosion provides a variety of products and services to protect your assets from external corrosion in a cost effective way using skilled, talented technicians and conventional and state of the art techniques as required. In addition, Providence Corrosion provides Phase I and 2 ESAs, EM surveys and reclamation and remediation supervision and consultancy services.

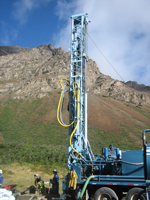

Cathodic Protection

Cathodic Protection (CP) is a corrosion control method that first known use was almost 200 years ago. It is widely employed to protect buried or submerged metallic structures against corrosion.

In North America, there are more than 2,000,000 kilometres of oil and gas pipelines. This entire infrastructure requires an effective CP system effectively operating 24/7.

We can assist your company in maintaining the integrity of these valuable assets by providing a superior external corrosion protection system. We excel in all phases of CP, including the engineering FEED phase, detailed design, construction management and execution, commissioning, operation, maintenance, regulatory surveys, specialized testing, etc.

Do not hesitate to contact us to improve through innovative techniques the CP aspect in your operations.

External Corrosion Direct Assessment

The external corrosion direct assessment (ECDA) is a structured process developed by NACE International in 2001 and is intended to improve safety by assessing and reducing the impact of external corrosion on pipeline integrity.

ECDA is an effective preventative measure as it can detect areas where

defects may form in the future rather than only identifying areas where

defects have already formed.

ECDA applications can include but are not limited to assessments of external corrosion on pipeline segments that:

* Cannot be inspected using other inspection methods

* Use innovative inspection methods to identify areas of future corrosion

* Establish a reassessment interval

* Manage future corrosion as an area of primary interest.

ECDA may detect other pipeline integrity threats, such as mechanical damage, stress corrosion cracking (SCC), and microbiologically influenced corrosion (MIC).

Surveys And Inspections

Field inspection/survey is a fundamental component of any integrity management plan.

We conduct regulatory CP surveys, specialized pipeline integrity surveys, above-ground inspections, aerial surveillance, stress-corrosion cracking direct assessment (SCCDA), grounding system inspection, soil corrosiveness surveys, cathodic rectifier monitoring programs, external corrosion direct assessment (ECDA) techniques such as CIS, ACVG, DCVG, PCM, DOC, dig

integrity programs, coating inspections and evaluations, water-body crossings, pressurized and rotary equipment inspections, etc.

We execute this work using in-house and external corrosion technologists and engineers that are either NACE or API certified.

AC Mitigation Analyses

The design of a pipeline in close proximity to a high-voltage transmission powerline must address safety and pipeline integrity issues relating to AC interference in accordance with current regulations. Pipeline operations and pipeline integrity personnel can both be at risk from induced AC voltages and elevated ground voltages due to phase faults and lightning strikes.

Three coupling modes can exist between the transmission powerline and the pipelines as detailed below:

* Electromagnetic (inductive) coupling: can result in hazardous voltages and current being induced on buried or above ground pipelines that are paralleled by a nearby transmission powerline

* Electrostatic (capacitive) coupling: is experienced during the construction of a pipeline, where long sections of pipe may rest above-ground near a high-voltage transmission powerline.

* Ground current (conductive) coupling: can cause hazardous voltages on buried pipelines when a short circuit current from a phase-to-ground fault enters the ground near the fault location and returns to the substation through the earth and nearby metallic conductors.

Thanks to state-of-the art simulation software, we offer AC interference engineering assessment services.

Integrity And Engineering

Our team of consultants focus on providing full lifecycle integrity management and operations support. We offer a unique blend of technical expertise and extensive practical and on-site experience.

For either green or brown projects and operations requiring cost-effective solutions to extend the service life of your pipeline network or pressurised equipment, our experts execute programs to ensure the safe and reliable operation of these assets.

Our NACE and API Certified Integrity Specialists have extensive experience in developing corrosion prevention FEED, Detail Design, Fitness for Service Assessments, Engineering Specifications, Integrity Management Programs that are compliant with applicable customer and industry regulations, standards, and recommended practices including API, ASME, NACE and CSA.

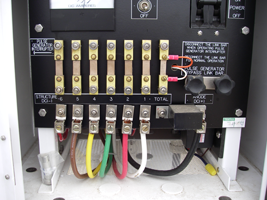

Materials

We provide a wide range of CP materials and the technical support necessary in the selection of appropriate materials. Some of the materials we supply include rectifiers, sacrificial and impressed current anodes, test stations, junction boxes, reference electrodes, flange insulation kits, direct burial cable, remote monitoring devices, isolation/fault protection devices, casing insulators, etc.

Environmental Services

ENVIRONMENTAL SITE ASSESSMENTS (ESA):

Alberta Environment requires oil and gas operators to conduct Phase 1 environmental site assessments on upstream oil and gas facilities following abandonment and prior to reclamation. Operators must also submit a Phase 2 ESA report on sites where the Phase 1 ESA has indicated there was a likelihood of contamination or there was insufficient information to determine whether contamination may be present. Providence Corrosion can assist operators with the elaboration of ESA Phase 1 and 2 reports, as required.

RECLAMATION AND REMEDIATION:

Providence Corrosion can support oil and gas operators during well sites reclamation through the coordination and supervision of reclamation activities to assure well sites reclaim land conditions and meet government regulations. Our company can also provide support during the reclamation certificate application through the AER. In addition, Providence Corrosion can prepare remedial action plans to meet government regulations.

EM SURVEYS, SOIL INVESTIGATION AND AERIAL PHOTOGRAPHS:

These investigation tools are used to complement regulatory ESAs. Providence Corrosion can perform Electromagnetic (EM) ground conductivity surveys to determine the extent of environmental damage in a non-intrusive way. In addition, our company can collect representative soil samples for laboratory testing and determination of the contamination volume. All data can be uploaded in a Geographic Information System’s map with the aerial site photographs.